The Evolution of Amazon’s Game-Changing Inventory System

Amazon has developed one of the most sophisticated inventory management systems in retail over the last twenty years. What began as a simple online bookstore has evolved into a complex operation that handles millions of orders every day. The system we see today is the result of years of improvement and innovation as Amazon has adapted to meet increasing customer expectations.

From Reactive to Predictive: Forecasting Demand at Scale

In its early days, Amazon managed inventory similarly to traditional retailers, responding to sales trends and restocking as needed. However, as the company grew rapidly, this straightforward method became insufficient. This prompted Amazon to create advanced analytics and machine learning systems capable of predicting future demand by analyzing billions of data points. Rather than solely relying on past sales, the system now takes into account numerous variables to foresee what customers will desire before they even place an order.

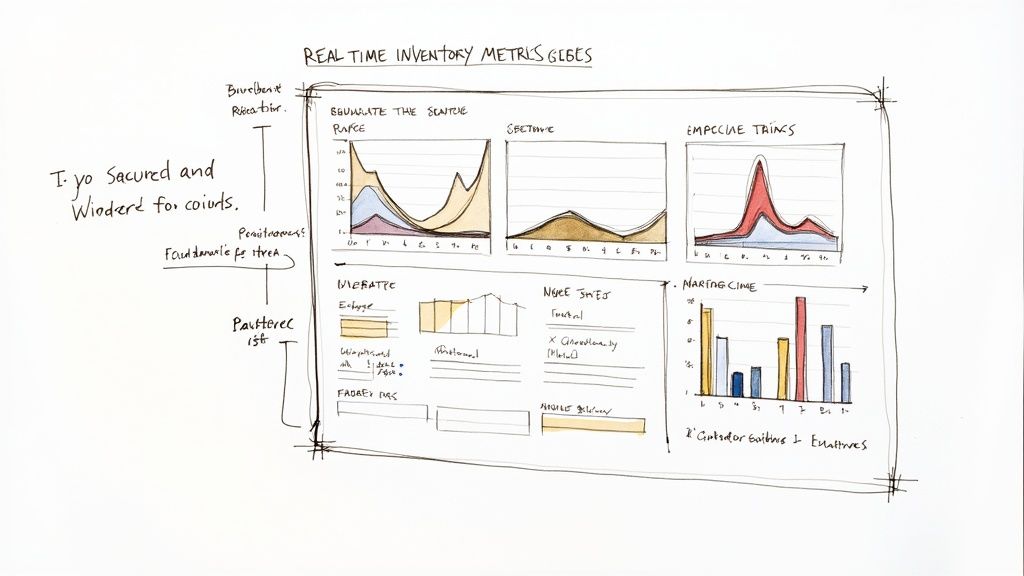

The Power of Data: Unlocking Insights for Inventory Management at Amazon

The secret behind Amazon’s predictive abilities lies in its extensive data collection and analysis. The system evaluates everything from historical purchase data to real-time browsing behaviors and even weather predictions. This wealth of information enables Amazon to move beyond mere speculation—inventory decisions are now grounded in solid patterns and trends. Additionally, the system offers detailed probability forecasts, providing sellers with a clear understanding of potential outcomes when managing their stock levels.

Building a Robust Framework: The Core Components

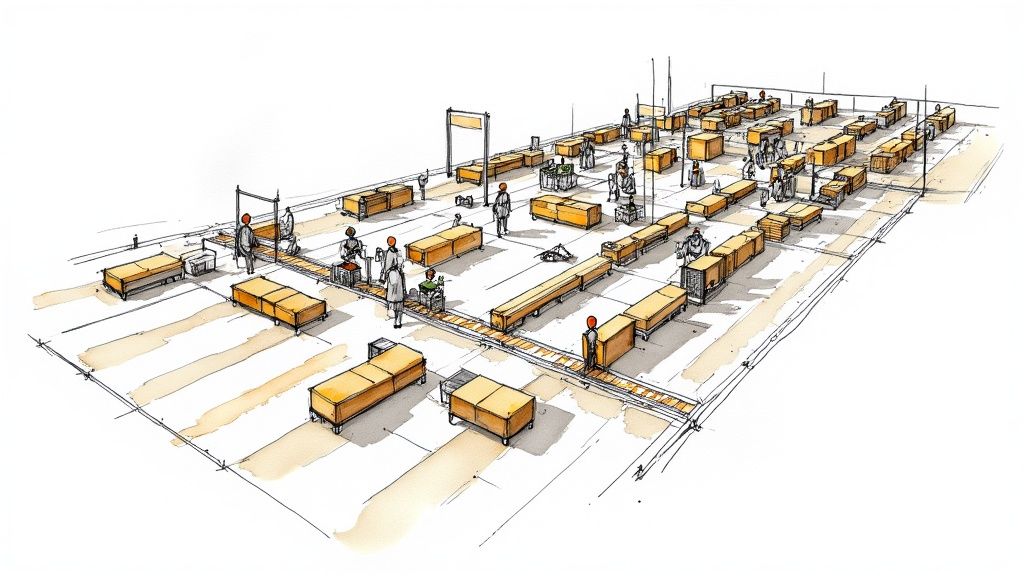

Amazon’s inventory system thrives due to several essential elements working in harmony:

- Real-time Tracking: GPS devices and RFID tags continuously monitor inventory location and status.

- Automated Warehouses: Intelligent robots and systems efficiently transport products through fulfillment centers.

- Warehouse Management System (WMS): A tailored platform orchestrates millions of daily inventory movements.

- Supplier Coordination: Strong partnerships with vendors ensure a smooth and timely flow of products.

These elements work in harmony to maintain optimal inventory levels while keeping costs low. The results are impressive—Amazon’s inventory turns over approximately 10 times faster than that of its competitors. With over 185 fulfillment centers globally, the company employs intelligent algorithms to position products strategically for both speed and efficiency. This meticulous coordination of technology, data, and logistics has played a crucial role in establishing Amazon as a retail giant.

Breaking Industry Records: Inside Amazon’s Lightning-Fast Inventory Turnover

Efficient inventory movement is a key factor in Amazon’s success. By ensuring a smooth flow of products, they can provide competitive prices, maintain stock availability, and lower storage costs. Let’s explore how Amazon’s technology and operations collaborate to achieve these remarkable outcomes.

Real-Time Visibility: The Foundation of Speed and Accuracy

Similar to how air traffic controllers monitor flights, Amazon utilizes sophisticated tracking systems to oversee millions of products in real-time across their warehouses. Their custom robotics, RFID technology, and sensor networks work in unison to pinpoint the exact location of every item. When there’s a sudden surge in demand for a product, the system promptly dispatches robots to prioritize picking and packing those items, ensuring swift delivery. This accurate tracking enables Amazon to adjust inventory levels immediately based on actual customer orders.

The Strategic Balancing Act: Inventory Velocity vs. Stock Levels

Rapid inventory movement necessitates a careful balance between speed and maintaining sufficient stock. Amazon excels in this area through intelligent data analysis. Their systems analyze historical sales, customer browsing habits, and even weather patterns to forecast demand accurately. Imagine it as a perfectly choreographed dance—products arrive at warehouses just as customers are ready to purchase them. This precise timing allows Amazon to fulfill customer needs while minimizing excess storage costs.

Minimizing Holding Costs, Maximizing Availability: The Amazon Advantage

Quick inventory turnover leads to significant cost savings. When products spend less time in warehouses, Amazon incurs lower expenses for storage, insurance, and the risks associated with outdated inventory. These savings enable them to offer competitive prices while ensuring items are readily available for customers. Their sophisticated Warehouse Management System effectively coordinates all these elements with impressive accuracy, enhancing their inventory efficiency.

Technology at the Forefront: Driving Extraordinary Results

Warehouse automation experts highlight that Amazon’s success stems from the seamless integration of its technologies. The synergy of robotics, RFID tracking, advanced software, and data analytics produces outcomes that surpass what any individual system could achieve. This cohesive strategy allows Amazon to consistently establish new benchmarks for inventory management efficiency. By continually investing in and refining these systems, Amazon secures its status as the leader in online retail operations.

Mastering the Global Fulfillment Network

Amazon’s extensive network of over 185 fulfillment centers serves as the foundation of its inventory operations on a global scale. These facilities function as essential hubs within a connected system, facilitating quicker delivery times and reduced shipping costs that directly benefit customers.

The Strategic Placement of Inventory: An Orchestrated Dance of Logistics

Locating a single item among millions in a warehouse the size of several football fields is a daunting task. To address this, Amazon employs intelligent inventory placement algorithms that consider anticipated demand, product sizes, and the distance between fulfillment centers and customers. For example, high-demand items are typically stored closer to packing stations or in warehouses situated near major population centers. This strategic placement accelerates order picking and packing, enhancing the overall efficiency of the fulfillment process.

The Brains of the Operation: Amazon’s Warehouse Management System

At the core of Amazon’s fulfillment network is its warehouse management system. Acting like an air traffic controller for products, it orchestrates millions of inventory movements each day—from receiving new stock to preparing items for shipment. The system keeps track of every product’s real-time location, monitors inventory levels, and helps avert bottlenecks before they arise. This meticulous coordination ensures that products flow seamlessly through Amazon’s vast network of fulfillment centers.

Location, Location, Location: Optimizing for Speed and Cost

Amazon strategically selects the locations of its fulfillment centers based on various factors. By building near major transportation hubs, they can reduce shipping times and costs. Placing warehouses close to large customer populations results in shorter delivery distances, enabling Amazon to maintain its renowned fast shipping speeds. This carefully planned network of locations is vital to their overall inventory management strategy.

The Interconnected Web: A Symphony of Efficiency

Instead of functioning in isolation, Amazon’s fulfillment centers operate as an integrated network to enhance inventory distribution and order fulfillment. If one center experiences a shortage of a product during peak demand, the system can automatically redirect orders to another location with available stock. This interconnected strategy ensures that products are accessible to customers no matter where they are, showcasing how Amazon’s adaptable network keeps inventory flowing efficiently throughout its entire system.

The Technology Stack Powering Amazon’s Inventory Excellence

Supporting Amazon’s extensive network of fulfillment centers is a sophisticated technology infrastructure that makes it all feasible. Their inventory management system merges custom software, advanced data analysis, and automation to handle millions of daily orders while achieving outstanding inventory turnover rates.

The Nerve Center: Amazon’s Warehouse Management System

The heart of Amazon’s operations lies in its specially designed Warehouse Management System (WMS). Much like an air traffic controller managing flights at a bustling airport, the WMS orchestrates every facet of warehouse activities—from receiving new stock to dispatching completed orders. It monitors the real-time position of each item, enabling workers to follow the most efficient picking routes and fulfill orders swiftly.

Predictive Power: Machine Learning and Demand Forecasting

Instead of merely reacting to incoming orders, Amazon leverages data to anticipate demand. Their systems sift through a multitude of data points—historical sales data, customer browsing patterns, and even weather predictions—to forecast what products customers are likely to purchase. This proactive approach ensures they stock the right items in appropriate quantities. For instance, if forecasts indicate impending rain in certain areas, the system will make sure those warehouses are well-stocked with umbrellas.

Robotics and Automation: The Muscle Behind the Operation

Amazon has woven robotics into its fulfillment centers to manage routine tasks such as moving inventory and picking orders. These automated systems work in harmony with the WMS, receiving directives and offering real-time updates on inventory levels. The robots take care of the heavy lifting, allowing human employees to concentrate on more intricate tasks. This blend of human and machine capabilities is crucial for handling Amazon’s enormous order volumes.

Real-Time Tracking and Visibility: RFID and Beyond

Monitoring millions of items necessitates continuous oversight. Amazon employs RFID tags and barcode scanners to track inventory movement throughout its network. This technology provides them with accurate, real-time insights into the location of every item at any given time. Beyond simple location tracking, this comprehensive data allows Amazon to analyze traffic patterns within warehouses, optimizing layouts and pinpointing potential bottlenecks. The goal is to ensure that the right products are always available at the right time, facilitating quick shipping while managing costs effectively. This meticulous coordination of technology has established new benchmarks for large-scale inventory management.

Just-in-Time Mastery: Redefining Supply Chain Efficiency

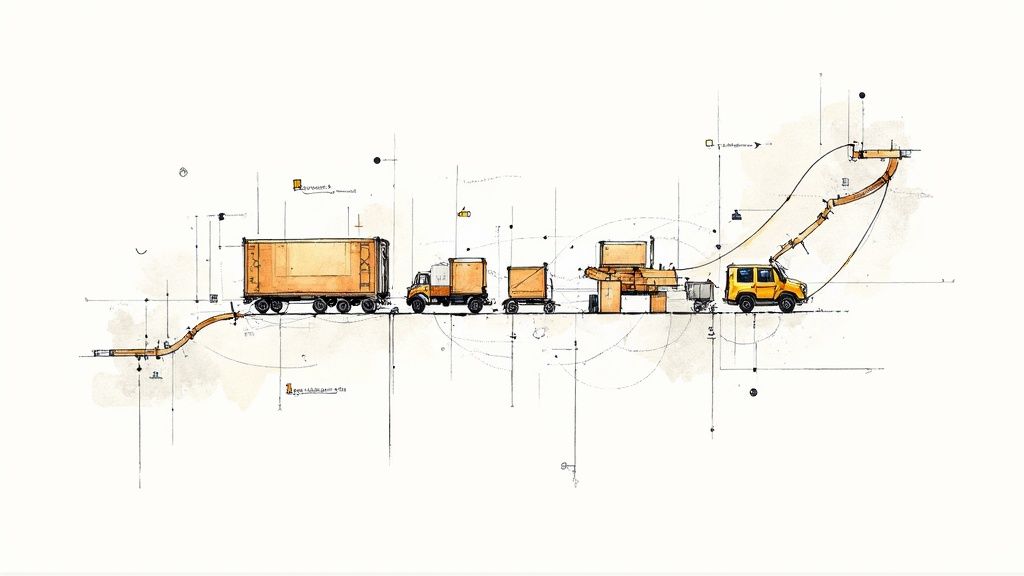

While Amazon’s extensive warehouses and robots often make headlines, their just-in-time (JIT) inventory system plays a crucial yet understated role in their success. By carefully timing deliveries and minimizing storage durations, Amazon keeps costs down while ensuring product availability. However, managing inventory on such a large scale demands precision and strong collaboration with suppliers.

The Predictive Power of Forecasting: Anticipating Demand

Consider the challenge of stocking a grocery store—excess inventory leads to waste, while insufficient stock results in empty shelves. Amazon faces this same dilemma, amplified across millions of products. Their solution involves data-driven algorithms that assess past sales, market trends, and even weather conditions to accurately forecast their stock needs. This enables them to order the right amounts at the right times, avoiding both stockouts and surplus inventory.

Supplier Relationships: The Cornerstone of JIT Success

Robust supplier partnerships are essential for just-in-time inventory management. Like a well-coordinated dance, Amazon communicates its needs, and suppliers respond with impeccable timing. This requires effective communication, shared objectives, and trust developed over time. Amazon’s supplier management systems facilitate this intricate flow of goods, allowing for swift adjustments to changes in demand while maintaining minimal stock levels.

The Benefits of JIT: A Win-Win for Amazon and Consumers

Amazon’s JIT approach minimizes storage costs and reduces the amount of capital tied up in inventory. Products are quickly transferred from suppliers to customers instead of being stored in warehouses. This allows shoppers to receive fresh, in-demand items promptly, resulting in increased customer satisfaction and repeat purchases. Additionally, this system enables Amazon to remain agile and allocate resources towards growth rather than maintaining excess inventory.

Practical Implementation: Navigating the Complexities of JIT

Although JIT may appear simple, implementing it effectively at Amazon’s scale presents several significant challenges:

- Lead Time Variability: Supplier delivery times can change unexpectedly. Amazon tackles this issue through meticulous forecasting and maintaining open lines of communication with suppliers to identify potential delays early on.

- Demand Fluctuations: Sudden shifts in customer demand can disrupt well-planned inventory levels. Amazon utilizes data analytics to swiftly adjust orders in response to market changes.

- Quality Control: Ensuring product quality is crucial. Amazon collaborates closely with suppliers to establish quality standards and inspection processes, ensuring that customers receive items in excellent condition.

This careful balance of forecasting, supplier collaboration, and flexibility has enabled Amazon to set new benchmarks for inventory efficiency. By continually refining their JIT system, they are consistently discovering new ways to enhance customer service while managing costs.

Building the Future of Inventory Management

Despite its highly efficient fulfillment network and advanced technical infrastructure, Amazon remains committed to pushing the limits of inventory management. The company invests significantly in researching and implementing innovative solutions that improve stock handling, demand forecasting, and customer service. Let’s delve into how Amazon is shaping the future of inventory control.

AI-Powered Forecasting: Beyond Predictive Analytics

Amazon’s current forecasting systems are already impressive, but the company is working on even more advanced AI models capable of processing vast amounts of data. For example, these new systems will take into account social media trends, news events, and local weather patterns in addition to traditional sales data. This allows Amazon to predict demand with remarkable accuracy, knowing precisely which products to stock and where they will be needed. The outcome? Reduced waste, improved availability, and satisfied customers.

The Rise of Autonomous Warehouses

Amazon has made significant progress in warehouse automation, but the next phase is set to go even further. Imagine robots that can autonomously decide where to place items, how to retrieve them most efficiently, and even determine the best packing methods—all without human intervention. These intelligent systems learn from their experiences, constantly discovering ways to enhance warehouse layouts and workflows. The advantages include quicker processing, lower costs, and more streamlined operations overall.

Reinventing Supplier Collaboration

Close collaboration with suppliers is essential for effective inventory management. Amazon is exploring new methods to share data and coordinate with vendors more efficiently. Picture suppliers receiving real-time updates about stock levels and automatically adjusting their production schedules to align with demand. This direct communication removes uncertainty and helps avoid both stockouts and surplus inventory.

Building a Sustainable Supply Chain

With growing environmental concerns, Amazon is actively seeking ways to make its inventory practices more sustainable. The company is planning smarter delivery routes to reduce fuel consumption, transitioning to eco-friendly packaging materials, and exploring opportunities to reuse and recycle resources throughout its operations. These initiatives not only benefit the environment but also resonate with customers who prioritize sustainability.

From Reactive to Proactive: The Future Is Now

Amazon’s approach to inventory management emphasizes anticipating changes rather than merely reacting to them. By leveraging AI technology, automated systems, and stronger supplier relationships, the company can identify and resolve potential issues before they escalate. This proactive strategy ensures that products are consistently available for customers while minimizing costs and maintaining efficient operations.

Are you an Amazon FBA seller frustrated with losing money due to inventory discrepancies? Refunzo can help you reclaim your lost profits. Our cutting-edge solution uncovers potential refunds for lost or damaged inventory, overcharges, and more. Try Refunzo for free today.