Mastering the New Amazon Inventory Ledger Report

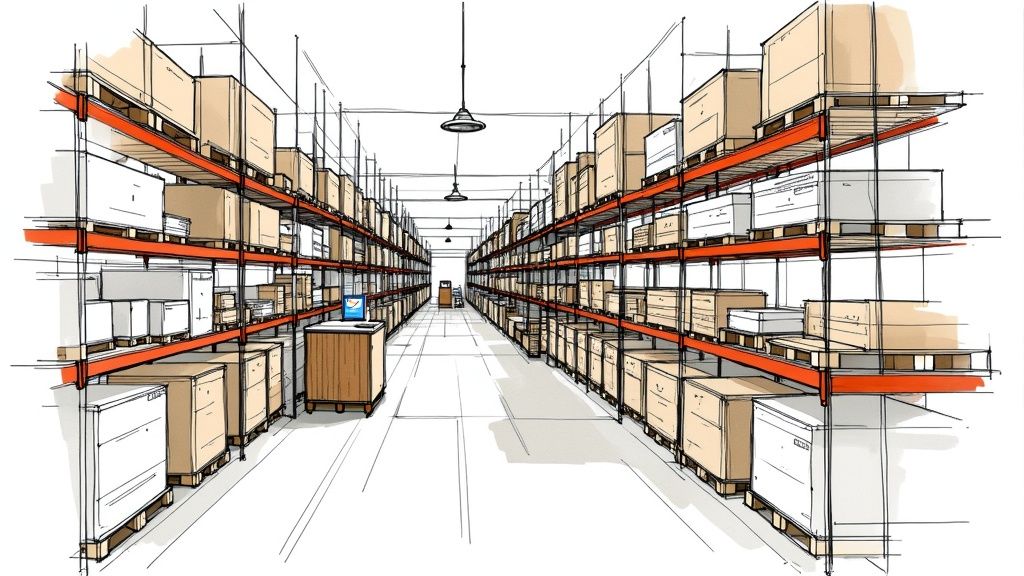

Amazon has made a big change to inventory tracking by combining six separate reports into one comprehensive Amazon Inventory Ledger Report. This new consolidated report gives FBA sellers much better visibility into their inventory movements. Many successful sellers I’ve spoken with say this single view has completely changed how they manage their stock and make decisions.

Understanding the Core Components

The report tracks every inventory event in detail – from when products arrive at warehouses to when they ship out to customers. You can see exactly what happened to each SKU, including how many units are sellable versus damaged. For instance, if items get damaged during fulfillment or by customers, you’ll know exactly how many and when it happened. This level of detail helps spot issues early and makes it much easier to get reimbursed under FBA policies when problems occur.

Getting More Insights from Different Time Views

Smart sellers are taking advantage of the daily, weekly, and monthly views to spot different patterns. The daily view helps catch problems quickly – like sudden spikes in damaged items. Weekly and monthly views reveal bigger trends, like seasonal changes in demand. As one seller told me, “The monthly view showed us our peak selling weeks were different than we thought, so we adjusted when we sent in inventory.” These insights help sellers stock the right amounts at the right times.

Practical Applications for FBA Success

Having all this data in one place makes it much easier to improve your FBA business. You can filter by SKU, FNSKU, or ASIN to zero in on specific products that need attention. For example, if you notice one product has more customer returns than others, you can look at improving the packaging. The report also helps maintain a good Inventory Performance Index (IPI) score by tracking key metrics like sell-through rate. This helps avoid costly storage restrictions from Amazon.

Reconciling Discrepancies and Maximizing Reimbursements

One of the best features is how the report helps track down missing inventory and get reimbursed for losses. The detailed data makes it simple to spot differences between your records and Amazon’s counts. Tools like Refunzo can help automate this process and file claims faster. Several sellers I know have recovered thousands in reimbursements they would have missed before. With practice, this report becomes an essential tool for running a profitable FBA business – helping you track inventory accurately, reduce costs, and recover losses when they occur.

“Decoding the Inventory Performance Index (IPI)”

The Amazon Inventory Ledger report contains essential metrics that shape your Inventory Performance Index (IPI) score. For FBA sellers, this score plays a direct role in determining your storage limits and associated fees. When your IPI drops too low, Amazon may restrict how much inventory you can send to their warehouses, which can limit your sales growth. On the flip side, maintaining a strong IPI gives you more storage space and helps avoid extra fees. Let’s examine how this system works and what you can do to improve your score.

Understanding the IPI Score

The IPI works like a credit score for your Amazon inventory, ranging from 0 to 1000, with 450 being Amazon’s minimum target. Your weekly score updates reflect how well you’re managing your inventory. For example, if you consistently sell through your stock at a healthy rate, your score will trend upward. But letting items sit unsold for long periods will pull your score down. This scoring system pushes sellers to find the sweet spot between having enough inventory to meet demand without overloading Amazon’s warehouses.

Key Factors Influencing Your IPI

Four main elements determine your overall IPI score:

- Sell-Through Rate: This shows how quickly you’re selling inventory compared to your stock levels. Higher sell-through rates mean you’re moving products efficiently.

- Excess Inventory: Having too many units sitting in warehouses hurts your score and increases your storage costs.

- In-Stock Rate: Keeping popular items available for purchase helps maintain a good score. Running out of stock too often can damage your IPI.

- Stranded Inventory: These are items that can’t be sold due to problems like incomplete listings or technical issues. Fixing stranded inventory quickly is essential for your score.

Strategies for IPI Improvement

Understanding these components is just the start – taking action to improve them is what counts. The Amazon Inventory Ledger report gives you the data needed to spot problems and opportunities. For instance, when you notice items selling slowly, you can run promotions or adjust prices to speed up sales. Similarly, fixing stranded inventory issues right away keeps your score healthy. Regular monitoring and quick responses to inventory problems make a big difference in your IPI performance.

Balancing Inventory Levels for Optimal Performance

Finding the right inventory level is like walking a tightrope – lean too far either way and you’ll have problems. Stock too much and storage fees eat into profits while hurting your IPI. Stock too little and you’ll miss sales opportunities. Many sellers use demand forecasting to guide their ordering, but markets can be unpredictable. That’s why keeping a close eye on your IPI score and making frequent small adjustments works better than occasional big changes. Success comes from staying responsive to what the data tells you about your inventory performance.

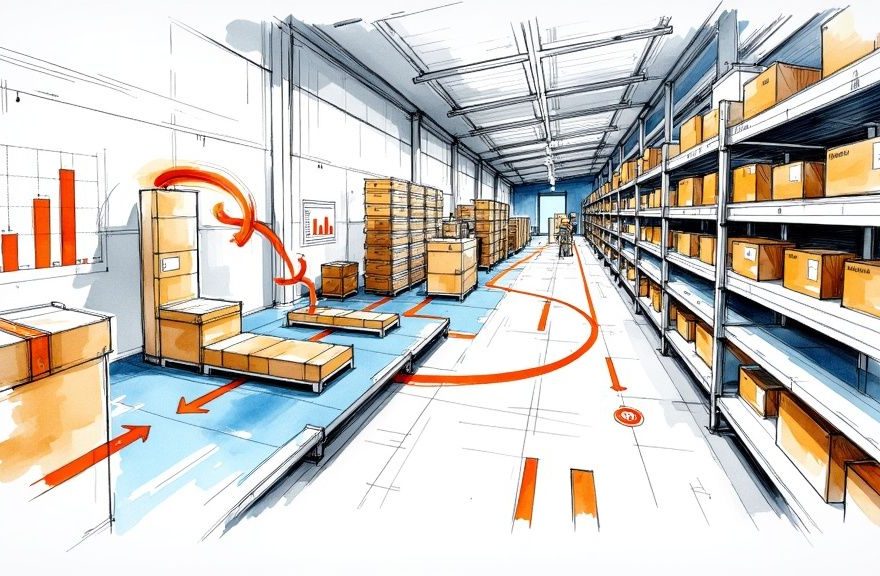

Understanding Amazon’s Fulfillment Network

Successfully navigating Amazon’s fulfillment network is crucial for efficient Amazon inventory tracking. This complex system, with over 185 fulfillment centers worldwide, presents significant opportunities for sellers to refine their inventory management and boost profits. This means understanding its intricacies is essential for staying competitive.

Leveraging the Network for Better Inventory Management

Top sellers don’t just send inventory to Amazon; they strategically distribute it across multiple fulfillment centers. Think of it like a diversified investment portfolio. Spreading your inventory reduces risk and maximizes potential. For instance, if one fulfillment center experiences unexpected delays, having inventory elsewhere ensures continued order fulfillment and prevents stockouts. This strategic approach is vital for a healthy in-stock rate, a key factor in a strong Inventory Performance Index (IPI) score.

Optimizing Inventory Placement for Cost and Speed

Effective inventory distribution also lowers shipping costs. By placing products closer to customers, sellers shorten transportation distances and, as a result, reduce shipping expenses. Additionally, this proximity leads to faster delivery times, boosting customer satisfaction and repeat business. Quick, reliable shipping is especially important in today’s e-commerce environment where customer expectations are high.

Adapting to Amazon’s Evolving Logistics

Amazon’s logistics are constantly evolving, with ongoing expansion and integration of new technologies. In 2024 alone, Amazon added 16 million square feet of new fulfillment center space in the US. This rapid growth requires a dynamic inventory tracking strategy. Sellers must adapt to these changes by regularly reviewing their inventory placement and adjusting their strategies to take advantage of new opportunities. For example, using programs like Amazon’s same-day delivery requires strategic inventory positioning to meet demanding delivery windows.

Maintaining Efficient Inventory Flow During Peak Seasons

Peak seasons, such as the holiday shopping rush, bring unique inventory management challenges. The surge in demand can strain even the most robust fulfillment networks. However, sellers who plan and adjust their Amazon inventory tracking strategies can navigate these hurdles effectively. This includes accurate demand forecasting, increasing inventory in strategic locations, and closely monitoring performance metrics to quickly identify and address potential bottlenecks. Adaptability and proactive management are crucial for efficient inventory flow and maximizing sales during these critical periods. Mastering Amazon inventory tracking within this dynamic fulfillment network gives sellers a significant advantage, ensuring business continuity and optimizing operations for long-term success.

Essential Daily Inventory Management Practices

Managing your Amazon inventory effectively requires a clear daily routine focused on key metrics and data points. While it may seem overwhelming at first, successful sellers develop efficient systems to stay on top of their stock levels. With the right tools and reports, you can spot potential issues before they affect your sales and profitability.

Streamlining Your Daily Amazon Inventory Tracking Routine

The Amazon Inventory Ledger Report is one of your most valuable assets for daily monitoring. This detailed report shows exactly how your inventory moves through the fulfillment process, from receiving to shipping. By checking it each day, you can quickly catch any concerning patterns – whether it’s an unexpected decrease in available units or an increase in damaged items. Think of this daily check as taking your inventory’s vital signs to maintain its health.

Many sellers also find success using specialized tools like Refunzo to simplify their daily tracking. This tool helps identify and process reimbursement claims for lost or damaged inventory automatically. Even small discrepancies add up over time, so using Refunzo or similar tools helps ensure you recover all eligible reimbursements. Making this part of your daily workflow protects your bottom line.

Identifying and Addressing Potential Inventory Issues

The real value comes from understanding what your inventory data means for your business. For instance, if you notice more units being reserved than usual, it could signal growing demand that requires larger restock orders. On the flip side, seeing your sell-through rate steadily drop may mean it’s time to adjust your pricing or marketing approach. Daily tracking gives you the insights needed to make smart decisions about your inventory strategy.

Maintaining Accurate Stock Levels and Avoiding Stockouts

Precise inventory tracking helps prevent one of the biggest risks to Amazon sellers – running out of stock. Stockouts hurt your search rankings and frustrate customers who may turn to competitors instead. When shoppers can’t buy your product because it’s unavailable, you lose both the immediate sale and potentially their future business. Regular monitoring lets you maintain optimal stock levels without excessive storage costs.

Setting up inventory alerts adds another layer of protection against stockouts. Define minimum thresholds that trigger notifications when stock gets low, so you can reorder before running out. This proactive approach keeps you ahead of inventory challenges rather than constantly reacting to them. By making these practices part of your daily routine, inventory management becomes a powerful tool for growing your Amazon business sustainably.

Solving Reserved and Stranded Inventory Challenges

Managing your Amazon inventory tracking effectively requires understanding and addressing two key challenges: reserved and stranded inventory. These inventory states directly affect your available stock levels and sales performance. Let’s explore what these terms mean and how to handle them properly.

Understanding Reserved and Stranded Inventory

Reserved inventory consists of items that are temporarily unavailable because they’re tied to pending customer orders or internal Amazon processes. When a customer places an order, those units immediately become reserved until shipment. Similarly, products moving between fulfillment centers show as reserved during transit. While these items aren’t currently sellable, they’ll return to available status once the associated process is completed.

In contrast, stranded inventory poses a more complex problem. These items sit idle in the fulfillment network, unable to be sold due to technical issues like listing errors or incomplete product information. For instance, if your product dimensions don’t match Amazon’s records, the items might physically exist in the warehouse but remain unsellable until you fix the discrepancy. This directly hurts your sales and needs quick attention.

Identifying and Addressing Stranded Inventory

Amazon Seller Central provides tools to spot and fix stranded inventory through the “Manage Inventory” section. This dashboard shows stranded items and explains why they’re unavailable. If a listing lacks required details like photos or descriptions, you can add the missing information to get the product to sell again. Sometimes technical issues or warehouse mistakes require contacting Amazon support for resolution.

Regular checks of your inventory tracking reports, especially the Amazon Inventory Ledger Report, help catch potential problems early. By watching the “disposition” status of your inventory in these reports, you can quickly spot stranded units and take action before they impact your bottom line.

Preventing Stranded Inventory With Proactive Measures

It’s much better to prevent stranded inventory than to constantly fix problems after they occur. This means implementing thorough quality checks before sending products to Amazon. Make sure your listings match physical products exactly, verify all product details are complete, and keep your records current. Think of it like maintaining a car – regular upkeep prevents breakdowns on the road.

Consider using inventory management software that connects with Amazon’s platform. These tools can automate listing management and warn you about potential problems before your inventory becomes stranded. This gives you an early warning system to catch issues while they’re still easy to fix. Following these practices consistently helps keep your Amazon inventory flowing smoothly.

Minimizing Reserved Inventory and Optimizing Stock Levels

While having some reserved inventory is normal, too much can signal underlying issues. High levels of reserved inventory might mean your processing or shipping times are lagging, which delays orders and affects your seller metrics. That’s why it’s essential to track reserved inventory alongside your other inventory metrics.

Supply chain hiccups often cause excessive reserved inventory. When shipments to fulfillment centers arrive late or have problems, it leads to longer processing times and more reserved stock. Working with reliable suppliers and planning efficient shipping routes can help your inventory move more quickly through the system.

Finding the right inventory balance is key to managing both reserved and stranded stock. You need enough products to meet demand without overloading your storage space. Too much inventory raises costs and risks items going obsolete, while too little means missed sales opportunities. Use your sales history and market patterns to predict demand accurately and order smart quantities. It’s similar to planning a road trip – you want enough fuel to reach your destination without carrying unnecessary extra weight.

By actively managing both reserved and stranded inventory challenges, you’ll keep your Amazon inventory tracking running efficiently, maintain healthy stock levels, and keep sales flowing strong. This ongoing attention to inventory management is essential for success on Amazon.

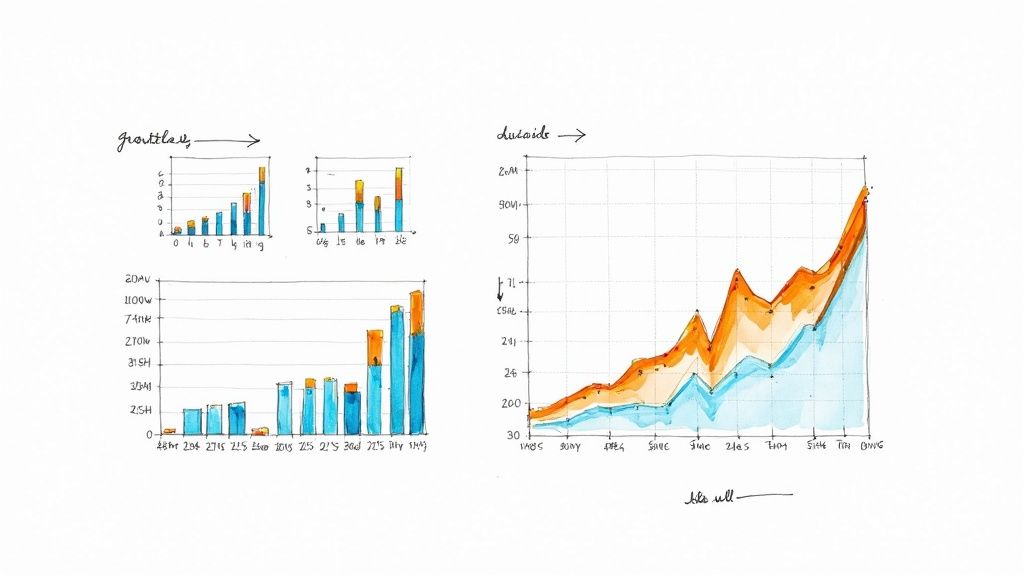

Advanced Optimization Techniques That Actually Work

Managing Amazon inventory requires going beyond basic tracking to achieve real business growth. Smart sellers know that fine-tuning their inventory management directly impacts their bottom line. Let’s explore proven optimization techniques that can help you maintain ideal stock levels while keeping costs down and profits up.

Implementing Effective Reorder Points

Setting the right reorder points is like having an early warning system for your inventory. Rather than waiting until you’re completely out of stock, proper reorder points trigger new purchase orders at the optimal time. To calculate your reorder point, consider your lead time (shipping/processing duration) and maintain safety stock as a buffer. For example, if you typically sell 10 units daily with a 7-day lead time, you might set your reorder point at 70 units plus safety stock. This simple but effective approach prevents stockouts while new inventory is en route.

Utilizing Advanced Reporting Features within Amazon Seller Central

Amazon Seller Central‘s Inventory Ledger Report provides deep insights that many sellers overlook. By examining data across different timeframes, you can spot important patterns in your sales history. For instance, monthly reports often reveal seasonal trends that let you stock up before demand peaks. The reports also track damaged or missing inventory, which is essential for filing reimbursement claims through services like Refunzo, helping protect your revenue.

Adapting to Market Changes and Demand Fluctuations

The market never stands still – customer preferences shift, competition changes, and external factors impact demand. Just like a captain adjusts course based on weather conditions, successful sellers constantly fine-tune their inventory strategy. Regular review of your sales data and market indicators helps you adjust reorder points and stock levels appropriately. This flexible approach helps maintain a strong Inventory Performance Index (IPI) score while avoiding both stockouts and excess inventory.

Leveraging Data Analytics for Informed Decision-Making

Smart inventory decisions come from analyzing real data, not hunches. Your sales metrics serve as a compass, pointing toward profitable choices based on actual market performance. By closely tracking key numbers like sales velocity, return rates, and profit margins, you can identify your best performers, products that need adjustments, and items to potentially discontinue. This evidence-based approach helps optimize your product mix for maximum returns.

Ready to improve your Amazon inventory management and boost your profits? Recover lost revenue and optimize your inventory performance with Refunzo.